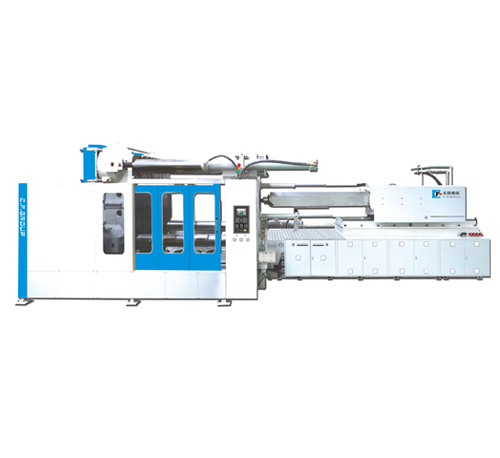

Caifeng Machinery adopts foreign imported materialsTwo plate injection molding machine

High-steel clamping mechanism ensures clamping accuracyHigh Precision and High Efficiency

Two plate injection molding machine

- Light weight, high strength

- increased bulk modulus, more compact structure, large bulk modulus and long mould opening stroke, the overall installation area reduced by 25%

- Simple Control Panel

- Fully functional, clear display, easy to learn operation, stable and reliable quality

- High performance and high precision controller

- Quick response, high control precision, excellent performance, complete monitoring functions

- Modular design, innovation and flexibility

- Injection molding modular design, flexible, to meet various injection molding requirements

- Servo system for material charging option

- Charging is more accurate, more energy saving, faster cycle time and higher precision

- Quick response and higher accuracy

- Centralized logic valve design, more agile response, high precision

Product List

Two plate injection molding machine |

Toggle injection molding machine |

Two-color, multi-color injection molding machine |

Color mixing machine |

Fast machine |

Do you encounter the following problems in choosing

the injection molding machine manufacturer?

Molding machine factory is too much, find the manufacturer that a product quality and production strength have assurance very hard?

Too many companies, can't find a design, manufacturing, after-sales service company?

Injection molding machine manufacturers good and bad, can not guarantee product quality?

Product production cycle is too long, delivery time is not guaranteed, can not deliver on time?

Is there a problem during the use of the product that the supplier cannot maintain?